1. Simple Marker Placement

Product Matrix

AcuRayScan Handheld Blue Light 3D Scanner

AI-enhanced with exceptional 3D visualization, resolving edge/hole defects effortlessly while achieving breakthrough precision.

Product Features

Max Accuracy

0.020 mm

Max Scanning Rate

5,400,000 measurements/sec

Max Volumetric Accuracy

0.015 mm+0.035 mm/m

Max Resolution

Up to0.01mm

Max Scanning Area

650 mmx550 mm

Scanning Modes

High-Speed Scanning

Fine Scanning

Deep Hole Scanning

Technical highlights

Exquisite Craftsmanship - Compact & Portable

High-quality material casing with precision machining and polishing. Compact and flexible body retains an ergonomic handle design for fatigue-free prolonged use, while maintaining a space-saving form for easy portability and operation.

High-Speed Efficiency - Massive Data Handling

Powered by next-gen cutting-edge algorithms and a camera frame rate surpassing industry standards, achieving an ultra-high scan rate of 5,400,000 measurements/second—enabling a smooth and efficient 3D digitization journey.

Primary Applications

Quality Inspection

Leveraging portability to advance metrology applications on the workshop floor, enabling efficient inspection to ensure products meet design specifications and providing reliable quality assurance.

Reverse Engineering

Delivering data feedback for optimized design and manufacturing, ensuring producibility and accelerating time-to-market.

General Manufacturing

Automobile Manufacturing

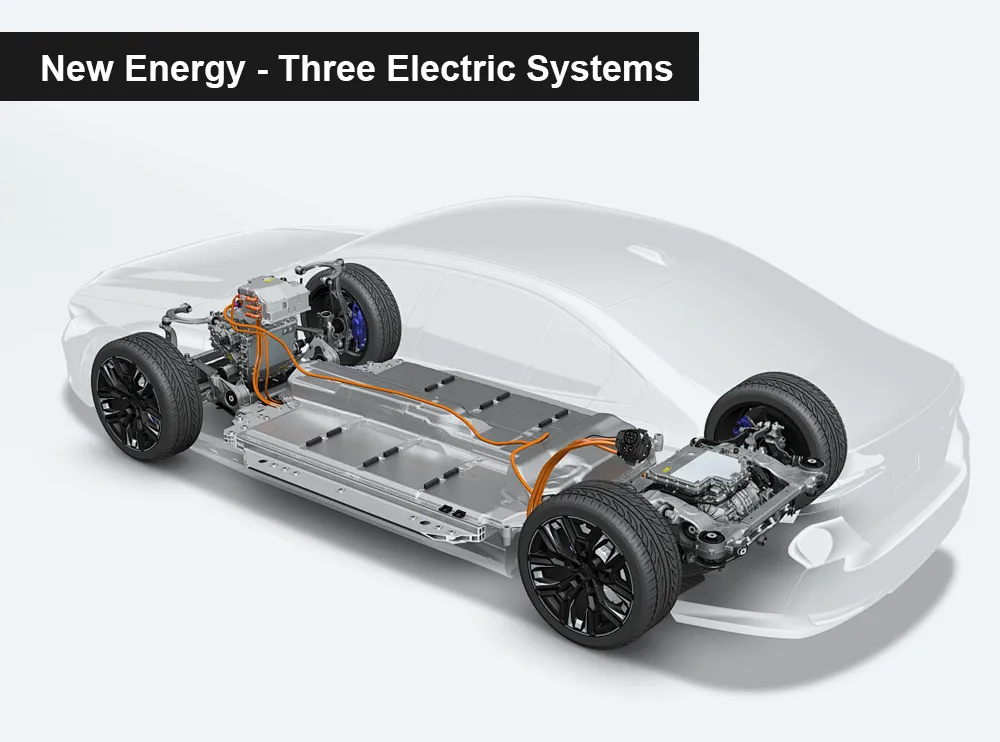

Automotive Industry

3D scanning technology is emerging as a cornerstone tool for digital transformation in the automotive industry, enhancing efficiency and reducing costs across the entire value chain - from R&D to after-sales services - while accelerating the development of new energy vehicles and personalized customization.

Automotive

Application Field:

Automotive Manufacturing

Surface Defect Detection

During the stamping process, sheet metal often exhibits issues such as surface unevenness, cracking, and excessive stretching.

Traditional CMM (Coordinate Measuring Machine) inspection requires a stable testing environment and lengthy measurement times, making it difficult to keep up with the fast-paced production demands of factories.

3D scanning technology can rapidly capture the 3D model of sheet metal, measuring key stamping features such as complete surfaces, holes, trimmed edges, springback, gaps, and flushness.

Automotive Customization

Personalized vehicle modification and customization often require 3D data of both interior and exterior components. However, such data is typically held by manufacturers and not publicly accessible.

With 3D scanning technology, professionals can accurately and efficiently capture complete 3D vehicle data, enabling streamlined design and modification processes.

Gap and flush analysis

3D scanning technology can accurately measure the gaps and flushes of vehicle exterior panels, guiding both pre-assembly processes and post-repair operations. It objectively reflects the gap and flush conditions at all measurement points, providing a complete inspection report for each vehicle. This ensures data visibility, quantifiability, and traceability.

Application Field:

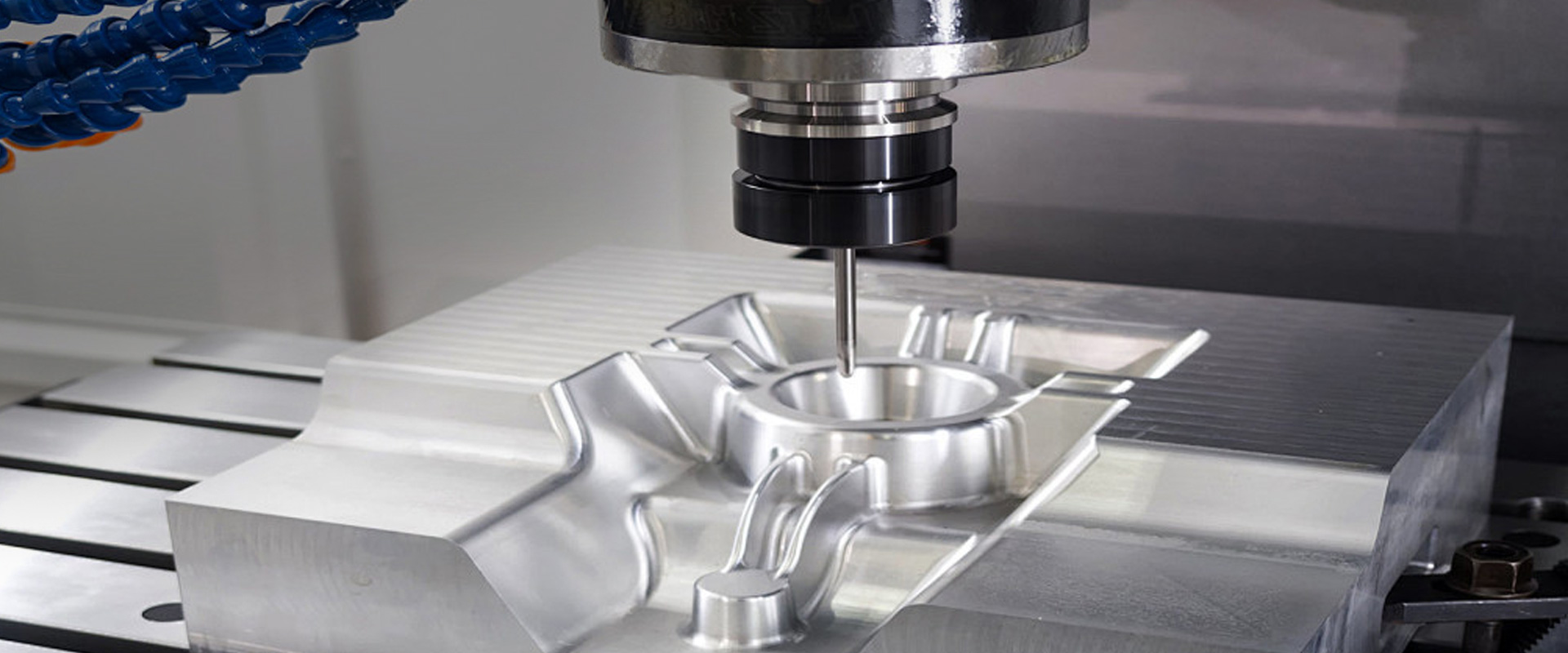

Mold Manufacturing

Allowance Inspection

During inspection, engineers typically add extra material—known as machining allowance—to molds and dies. 3D scanning technology assists engineers in verifying whether sufficient machining allowance exists and monitors the manufacturing process.

Machining Optimization

Ensuring the product has an appropriate machining allowance is crucial. For complex-shaped molds, rapid positioning of machining references is often required. 3D scanners help machine tools establish the machining coordinate system, significantly reducing the difficulty and errors associated with manual marking.

Post-Machining Inspection of Molds

Due to variations in operator handling and machining equipment, discrepancies may exist between the actual manufactured mold and the theoretical design. Therefore, it is essential to inspect critical features of the finished mold to ensure accuracy.

Mold Repair & Maintenance

Over prolonged usage, molds inevitably experience wear and deformation. 3D scanning technology enables rapid and quantitative assessment of deviations from the ideal mold geometry, providing precise guidance for technicians to perform targeted repairs and restore optimal performance.

Application Field:

Aerospace

Blade Profile Calibration

3D scanning technology captures the surface contours of curved blades and compares them with theoretical CAD models, generating tolerance deviation color maps to identify precise calibration direction and allowance margins. A single scanner can analyze blades of varying geometries, significantly reducing the complexity of traditional measurement methods.

Reverse Engineering

By acquiring high-density point clouds or mesh data of aerospace components via 3D scanning, engineers can use specialized reverse engineering software to reconstruct parametric CAD models from physical parts. Designers can further modify these models, streamlining the redesign process and accelerating iterations for legacy parts or performance upgrades.

Application Field:

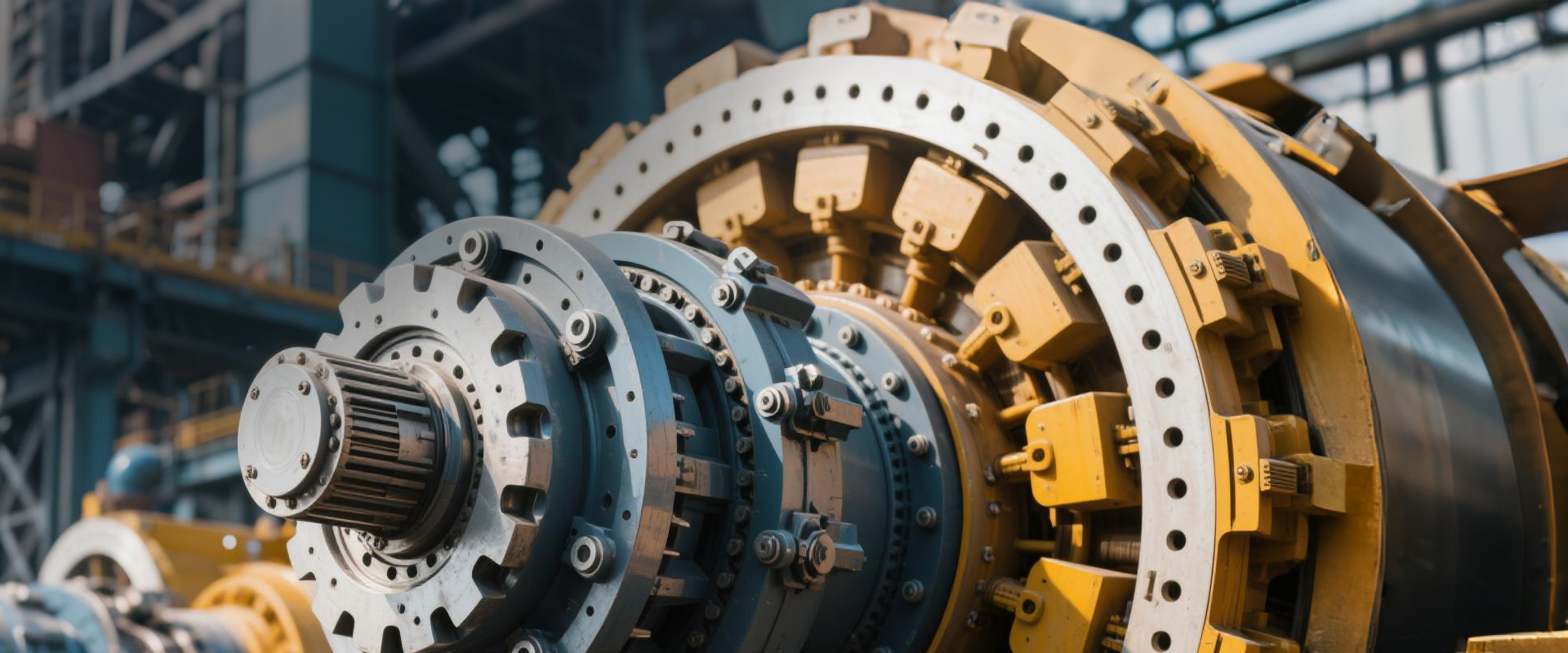

Energy & Heavy Industry

Raw Inspection

High-precision scanning of rough castings/forgings, comparing with CAD models to detect machining allowances and geometric tolerances.

Machining Allowance Inspection

Acquire the actual geometric data of rough blanks through 3D scanning, automatically compare with design models, and quantify machining allowances for each region.

Surface Defect Detection

During usage, the surfaces of large equipment may experience deformation, cracks, and irregular changes. Traditional measurement methods are unable to quantitatively analyze these variations. Three-dimensional scanning technology can monitor the changes in surface defects over time, playing a significant role in managing the product lifecycle.